After a few years of production of the paint bucket mold, due to the long-term high-speed and high-pressure injection molding, there will be core eccentric problem on plastic paint bucket mold, resulting in uneven wall thickness of the paint bucket. So how to solve the problem of paint bucket mold core eccentric in the production ?

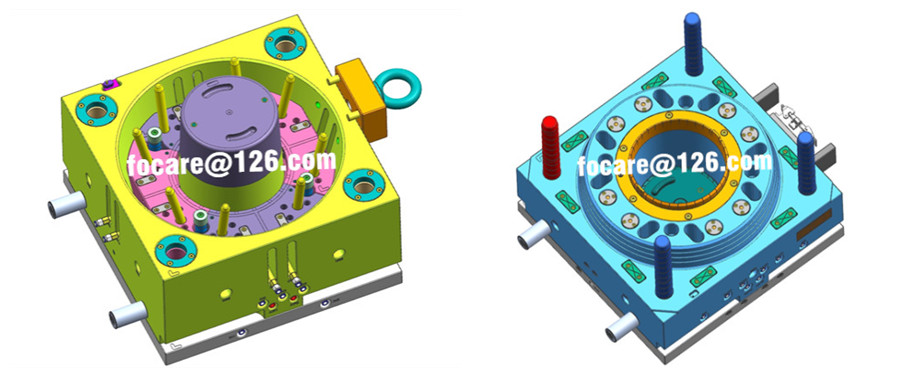

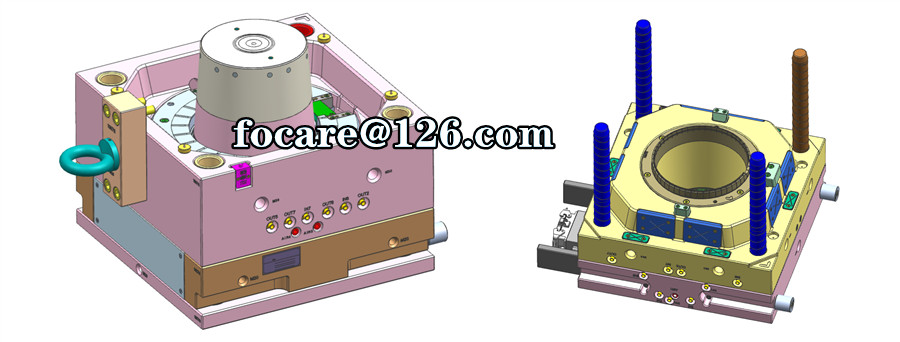

First of all, You need to check your paint bucket mold structure Generally, there are two types of the clamping structure of the bucket mold, one is circular clamping structure and the other is quadrangular clamping structure. For the two different mold structures. Of course, the way to solve the core eccentric is also different.

If your paint bucket mold is with a circular clamping structure, the only way is to buy a new paint bucket, or if you have tooling equipments, then you can re-processing the mold core to solve the paint mold core eccentric.

If your paint bucket mold with quadrangular clamping design, There are usually 8 sets wear plates on the side of the mold cavity, then you just need to adjust the wear plates to solve the problem of paint mold core eccentric, you can re-process the wear plate or place a copper sheet under the wear plate if you don’t have any tooling equipments.

Focare Mould is a professional and reliable paint bucket mould manufacturer, paint pail mold making factory, plastic paint bucket mould designers, bucket mould injection expert, if you have any problems of bucket moulds or want to buy a new mold, please contact me to focare@126.com, I will provide you with the best solution to meet your needs.

Name: Susanna Jia

Mobile:+8615215805151

Whatsapp:+8615215805151

Email:focare@126.com

Add:15#Jinchuan Rd. North industry HuangYan,Taizhou City,Zhejiang province ,China

We chat