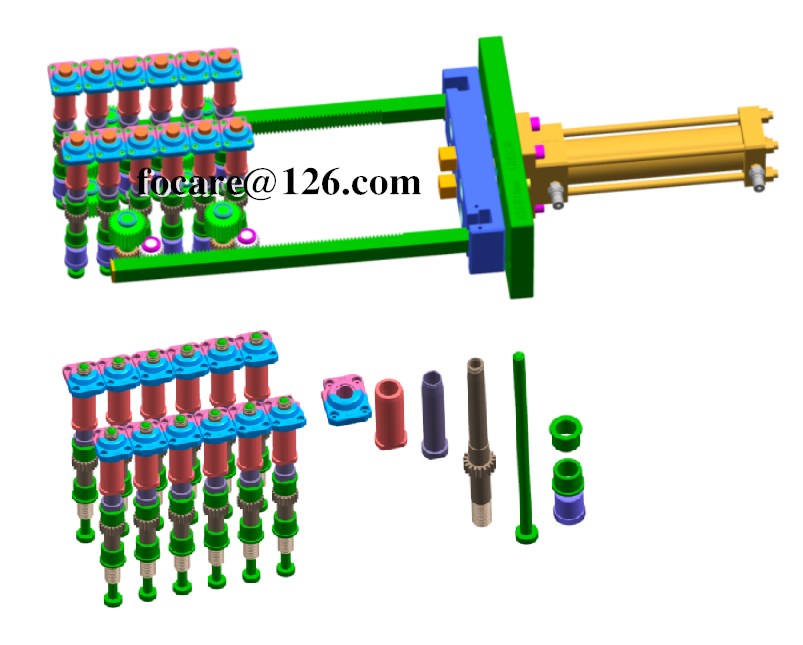

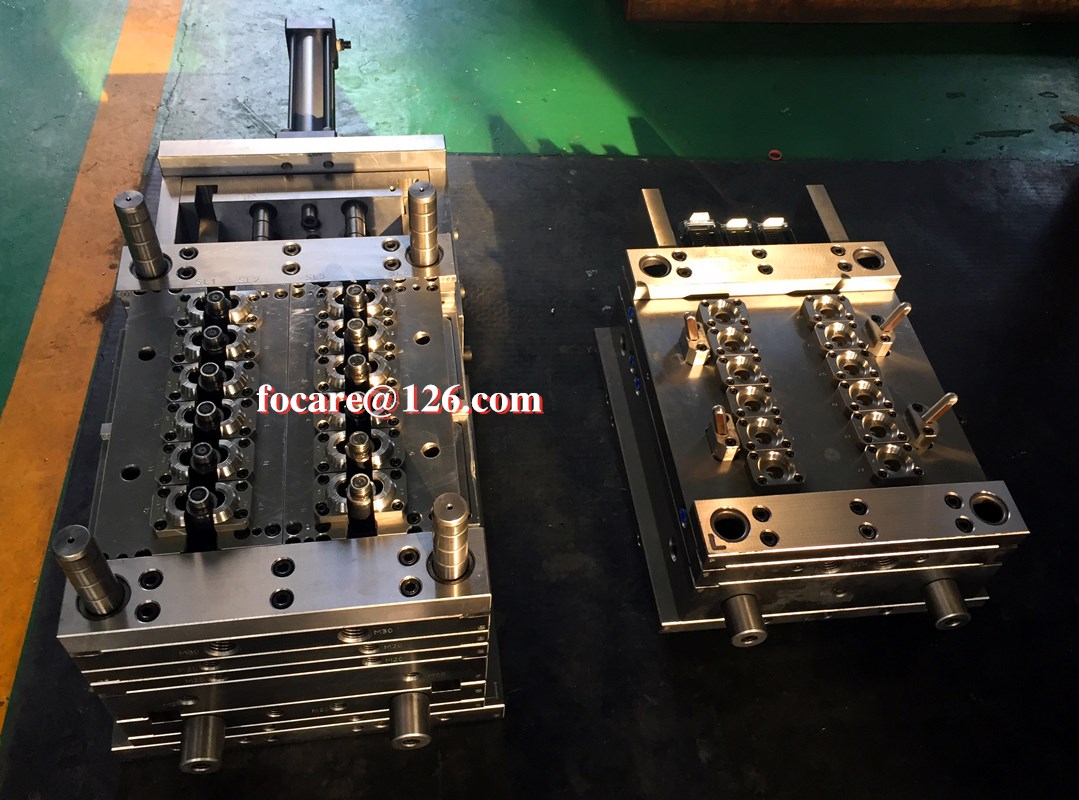

The working process of unscrewing ejection is when the plastic is injected into the mold. After has cooled, the threaded core starts to unscrew. The unscrewing mechanism works off of a rack and pinion and is powered by a hydraulic cylinder. Once the threaded core is fully unscrewed, the ejector system pushes a stripper plate forward to eject the cap.

Generally, the output of bottle cap is very large, so the unscrewing water bottle cap mold most long time operate at a high speed to reduce the cycle time and increase the output. So The unscrewing cap molds must also be high quality and reliable.We use imported hydraulic cylinder, high quality pinion and racks to ensure that the unscrewing cap mold allows long time work .

Focare Mould is a reliable cap mold automatic unscrewing solution provider. With our rich experience in making plastic cap molds with automatic unscrewing ejection,we have done many unscrewing cap molds,such as water bottle unscrewing cap molds,oil can unscrewing cap molds,cosmetic unscrewing cap molds,flip-top unscrewing cap molds,etc. If you want to get a high quality and high speed unscrewing cap molds, welcome to contact us.

Name: Susanna Jia

Mobile:+8615215805151

Whatsapp:+8615215805151

Email:focare@126.com

Add:15#Jinchuan Rd. North industry HuangYan,Taizhou City,Zhejiang province ,China

We chat