Focare

Mould-China plastic crate mold manufacturer with more than 10 years of

experience in making bottle crate molds.After ten years of experience in bottle box mold making,

we constantly update the structure design of bottle crate molds, improve the

machining accuracy , and improve the requirements of mold manufacturing and

testing, so our plastic crate mold quality can fully meet your high

requirements, we have also made bottle crate molds for world-renowned brands , such

as Pepsi, Coca cola, and received high praise from them.

As a professional plastic bottle crate mold manufacturer, how We build Plastic bottle crate Molds to Support Your Plastic Injection Business

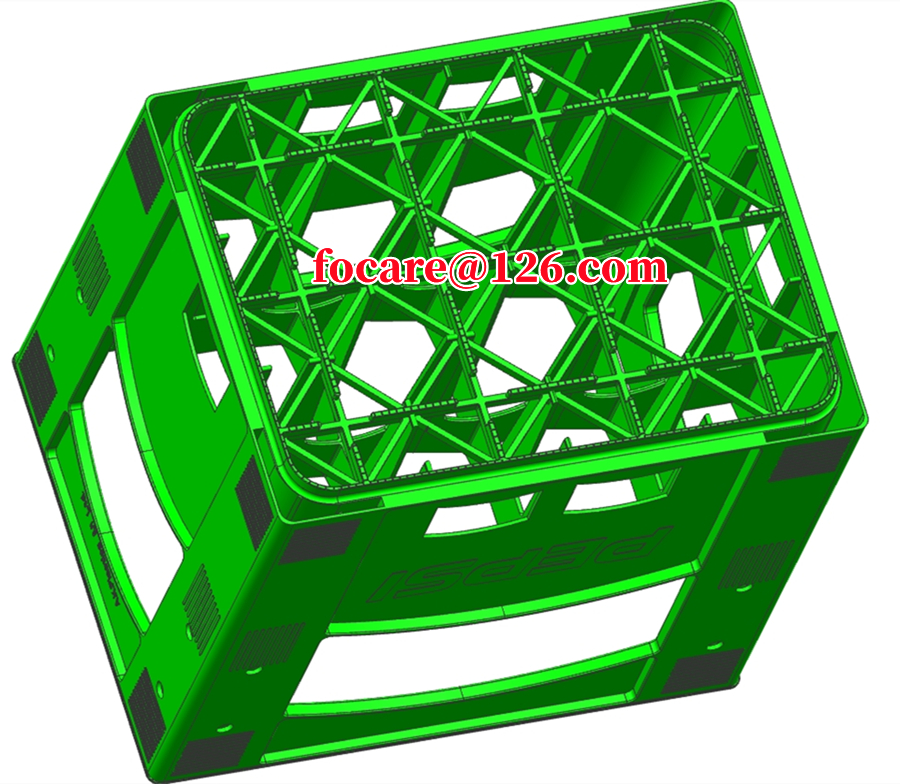

-Plastic Bottle crate mold design

To make a good bottle crate mold, Firstly, it is very important to have a perfect bottle crate mold design, a good and reasonable bottle crate mold constructure can affect the mold quality, mold life and actions. We have our own design team with rich experience in making bottle crate design. In addition to meeting your design needs, we can also provide you with professional design advice to avoid some problems in production.

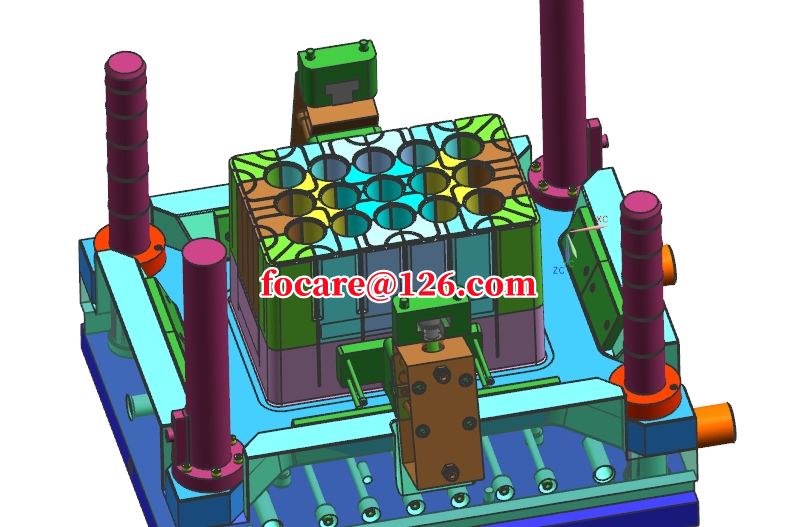

-Plastic Bottle crate mold processing

The mold design is to set the foundation of bottle mold, processing is the key to achieve the quality of bottle crate mold, to make a high-quality bottle turnover box mold, high speed milling machine must be used to ensure the accuracy of each parts, we have 6sets American high speed milling machines, which fully meet the high precision mold of different crate size.

-Plastic Bottle crate mold assembly

Plastic bottle crate mold assembly is one of the most critical steps of mold making procedure, all the parts machined or purchased need to be put together and required to be work functionality. Mold assembly job requires comprehensive understanding of mold structure as well as injection molding. Quality of plastic bottle crate mold assembly determines the mold precision, injection productivity.

-Plastic Bottle crate mold testing

Plastic bottle crate mold testing is the last step of mold production, it is to check whether the mold is qualified and whether the crate meets the customer's standard, During the mold testing process, we will check the mold action, molding cycle, hot runner system, etc. If there is no problem, we will let the mold run for 2-4 hours to ensure the mold can be produced stably,and the samples will send to customer for inspection

Cooperation with Focare Mould team will be your good choice for high level plastic bottle crate molds. With 10+ years of experience in making plastic bottle crate mold, We not just provide you a quality bottle crate mold ,but also technical support, we are not just your plastic bottle turnover box mold supplier, but your technical consultant.

Name: Susanna Jia

Mobile:+8615215805151

Whatsapp:+8615215805151

Email:focare@126.com

Add:15#Jinchuan Rd. North industry HuangYan,Taizhou City,Zhejiang province ,China

We chat